Products & Services

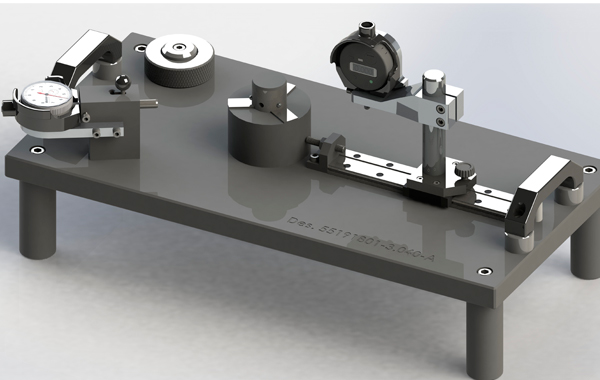

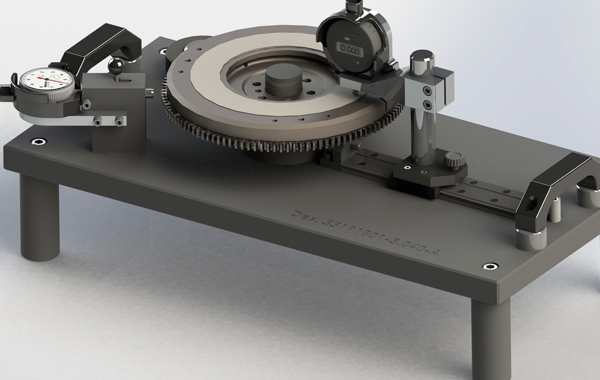

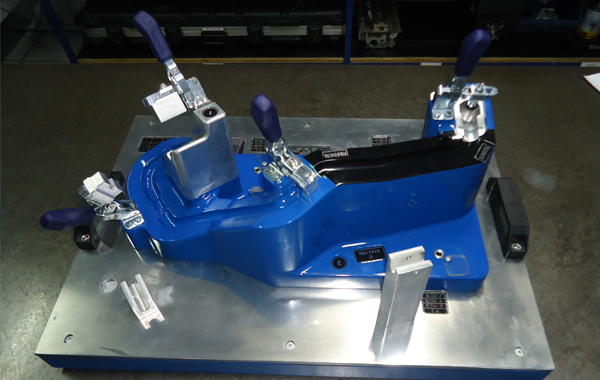

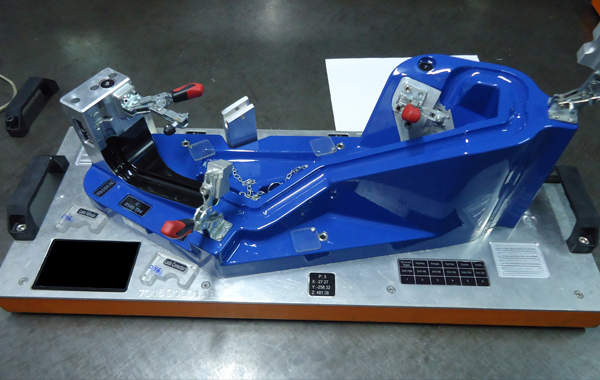

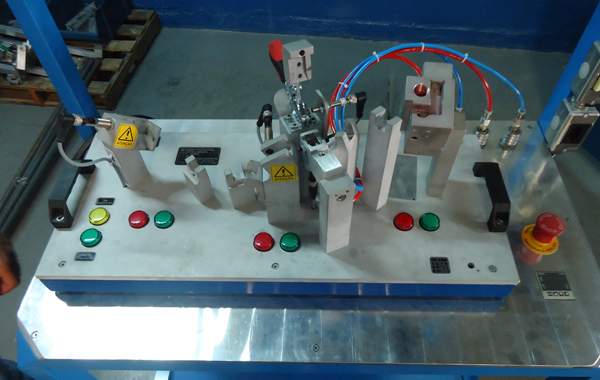

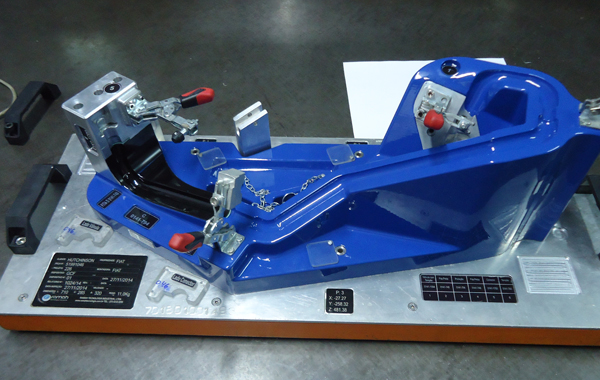

The Control Device is a fundamental concept in industrial processes, because each stage of production and equipment needs a rigorous inspection and efficiency guarantee. When accurate measurements are needed, industrial control devices are key mechanisms to ensure quality all factories.

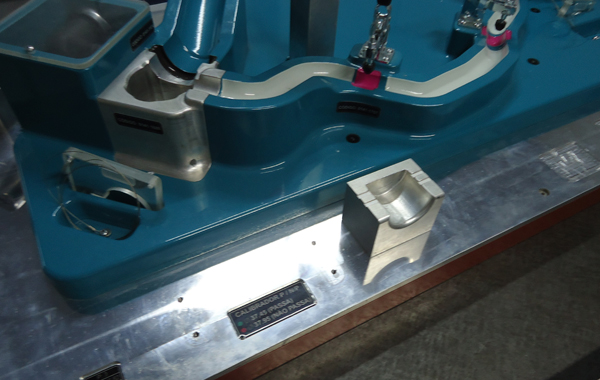

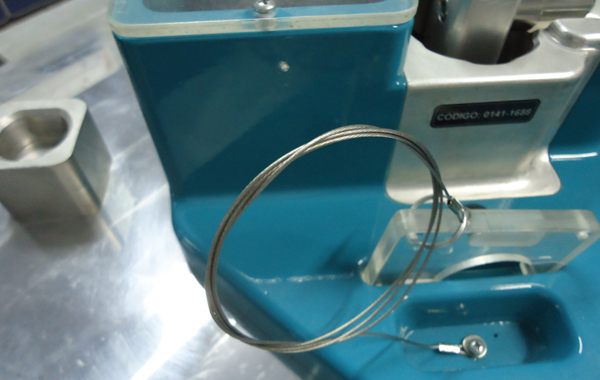

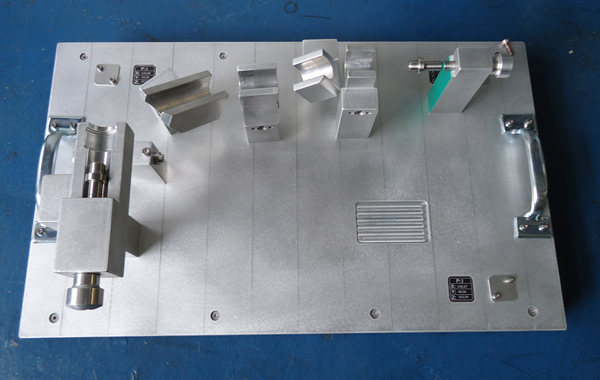

These devices are custom-made by highly specialized technical teams, which have at their disposal advanced tooling, according to the GDeT (Geometric Dimensioning and Tolerance) specification.

This means that these devices are able to check if the parts are being produced according to the defined parameters. In this way, they act as a quality inspection tool in the manufacturing and product adjustment processes. Thus, it is possible to guarantee the large-scale production of parts with precise measurements.

Different materials can be used in the manufacture of control devices, such as aluminum or steel and resin. The selection of raw material will depend on the industrial conditions to which the product will be submitted.

The control device is used to ensuring high customer productivity. To meet this objective, RAMAH has qualified team and high technology. These elements ensure control devices produced on time, with good durability, that meet regulatory standards and, above all, with efficiency in the measurement of parts.

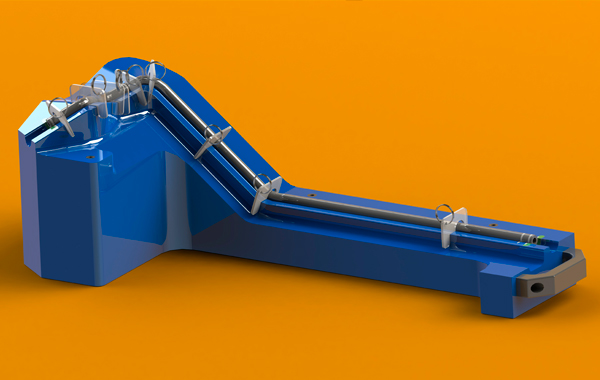

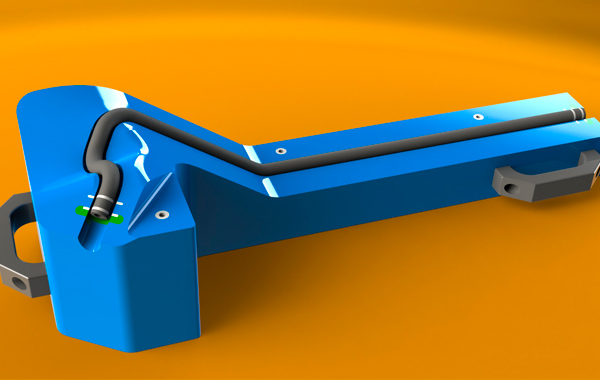

Productivity is the mission of this control device factory, other solutions are also offered that guarantee customers the best cost-benefit ratio of their manufacturing processes, such as:

2D machining with geometrized equipment with digital coordinate control

3D machining with CNC

Three-dimensional measurement with an accuracy of up to 0.001 mm